Digital Twin Platform

Digital Twin Platform

Driving digital transformation in large-scale aluminium production.

Driving digital transformation in large-scale aluminium production.

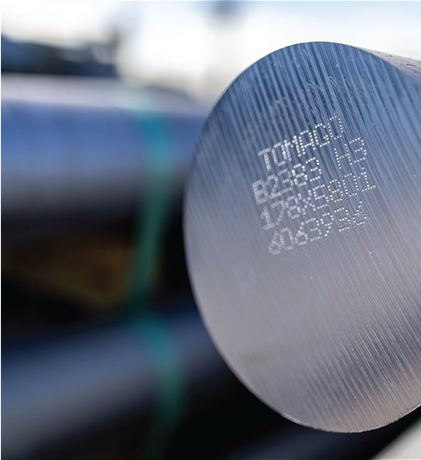

Tomago Aluminium

Tomago Aluminium

2024

2024

Digital Transformation

Digital Transformation

Services

Services

Solutions Architecture

IoT Integration

System Integration

Interface Development

End to End Project Management

Agile Collaboration

The Challenge

The Challenge

Tomago Aluminium, the largest aluminium smelter in the Asia-Pacific region, faced significant challenges with real-time digital tracking of their production process. The traditional methods used for monitoring and managing aluminium production were inefficient, prone to errors, and lacked the granularity needed for optimal efficiency and sustainability. This led to difficulties in accurately measuring and optimising resource usage, highlighting the critical need for an advanced, real-time observability solution to enhance operational efficiency and drive sustainability.

The Solution

The Solution

Jaegersoft partnered with Tomago Aluminium to develop a Digital Twin platform that revolutionised production monitoring. Using IoT sensors installed across the production line, the platform provided real-time tracking of key assets such as vehicles, ladles, and mobile equipment and visualised the entire production process in a digital replica. This innovative system automated data collection and analysis, minimising errors while delivering actionable insights to optimise production efficiency and sustainability.

The Results

The Results

The Digital Twin platform revolutionised operations at Tomago Aluminium, driving measurable impact across key business areas. This cutting-edge implementation has positioned Tomago Aluminium at the forefront of digital transformation, setting a new benchmark for operational excellence.

REAL-TIME VISIBILITY

Instant access to critical operational data for enhanced oversight and responsiveness.

OPERATIONAL EFFICIENCY

Streamlined workflows and optimised processes, reducing downtime and improving productivity.

INFORMED DECISION-MAKING

Data-driven insights empowering leaders to act with confidence and precision.

SEAMLESS INTEGRATION

Effortless connectivity with existing systems, ensuring minimal disruption and maximum value.

REGULATORY COMPLIANCE

Automated tracking and reporting to meet industry standards with ease.

FUTURE PROOF SCALABILITY

A flexible, scalable solution designed to evolve alongside Tomago Aluminium’s growth and innovation.